Clean and sustainable future flight, made possible by advanced materials

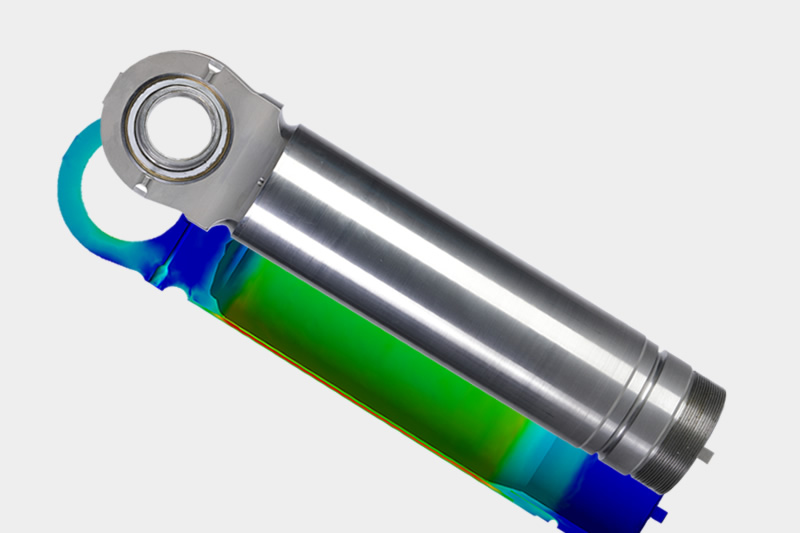

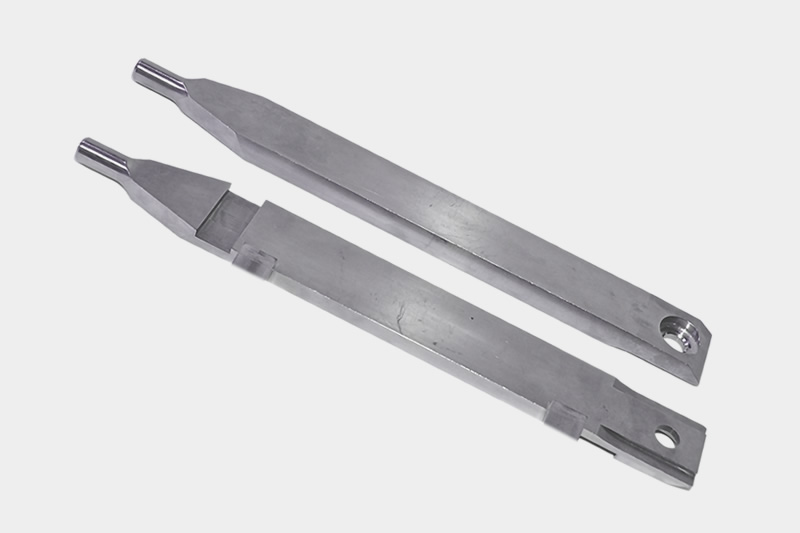

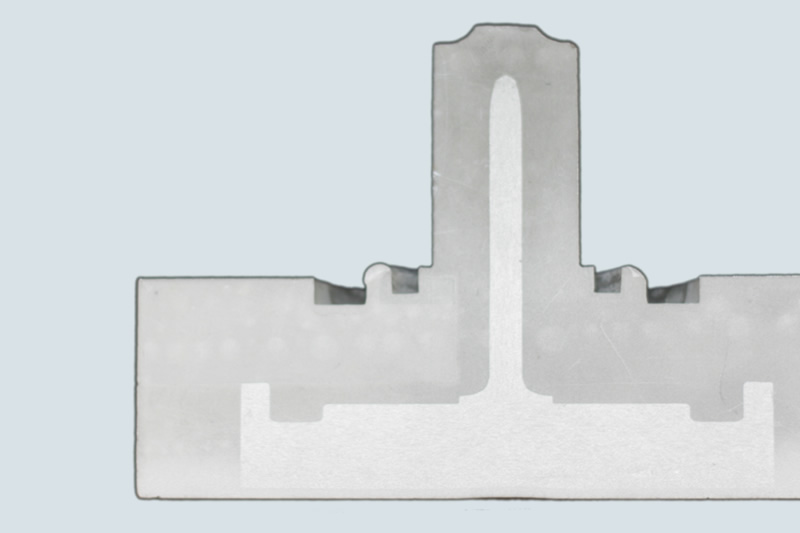

Metal Composites for Aerospace Applications

Reduced

system mass

Specific strength and stiffness 2x that of high-strength steel

Reduced

buy-to-fly ratio

Upto 85% reduced waste from net-shape manufacture

Extended

service life

Excellent fatigue life with very high compressive failure strength

Simplified

system integration

Robust metallic interfaces, compatible with standard joining methods

Corrosion

resistant

Eliminates need for REACH-restricted coatings

High thermal

stability

Reduced creep and low coefficient of thermal expansion

Partners and Collaborators